Titanal promises damping, stability and optimal power transmission. So it's no surprise that we use this material in a large number of our skis, since Kästle stands for maximum smoothness at high speeds.

HOLLOWTECH 2.0 is the first adaption of this patented Kästle core technology. The size of each HOLLOWTECH is uniquely adapted to the shovel design of each ski to enhance performance. This technology involves removing excess material from the tip of the ski, specifically from the "shovel" area. This targeted reduction in mass offers many key benefits.

The new, revolutionized HOLLOWTECH 3.0 has a two-tier construction: a new outer ring cuts out even more material and therefore even more weight. The size of the HOLLOWTECH is always precisely matched to the shovel of each particular model - for performance that's truly unbeatable.

Thanks to a carbon layer in the shovel, the entire construction is even more stable and lighter. The Hollowtech 3.0 Carbon convinces with its strong damping properties and is used exclusively in the MX model line.

Especially for our high-performance piste models and racing skis, we have further developed the Hollowtech 2.0. Even larger than before, it ensures greater stability, even at top speeds in the World Cup.

For the first time, the reduction of material is being extended to the entire shovel area. The development goals are to save even more weight, increase performance and optimize the handling characteristics for each ski. HOLLOWTECH EVO is used in the all-mountain and touring models (as glowing HOLLOWTECH EVO LUMINOUS).

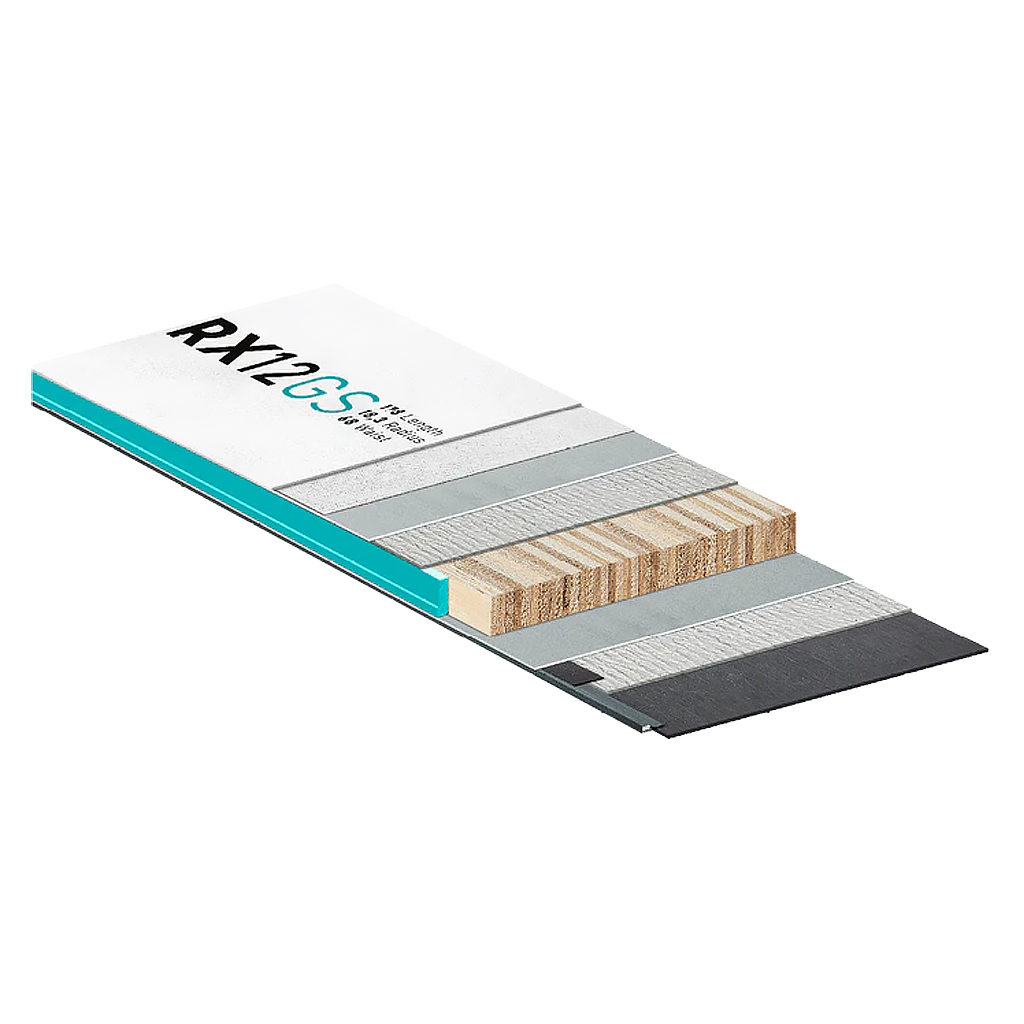

The choice of wood is determined by the desired properties of the ski in terms of stiffness, grip, stability, and weight. If the final product is to be stable, we choose a wood with a higher density, such as poplar or beech. A ski that should convince its rider with lightness and float, usually contains a lighter wood, such as paulownia. In many cases, however, we use a combination of different types of wood to meet all requirements. These are glued together and only then pressed with the remaining layers.

But why wood anyway? No other substance can provide the ski with the desired handling characteristics as well as this material - and retain them over a longer period of time. It is quite simply THE quality feature, which is why not only every Kästle has a wood core, but special attention is paid to its origin in the selection as well. Thus, we use up to almost 80% domestic woods, whose main supplier is located in Switzerland.

To be able to further vary the riding characteristics of our skis, Kästle skis utilize a variety of materials to achieve their renowned performance and durability. Key components include a wood core, often a blend of poplar and beech, which provides a balance of stability and energy. Titanal, a high-strength aluminum alloy, is frequently used as a top layer and within the core to enhance stability and power. Fiberglass is also a common inclusion, often in pre-preg form, adding to the ski's energy and consistency. Additionally, Kästle uses bases often made from recycled materials.

We build our Kästle skis with classic camber and distinguish between Standard Camber and Low Camber.

Benefits of Camber in Kästle Skis:

With Standard Camber, the ski center is clearly elevated and the contact points to the snow are far forward and back. The effective edge is longer and the ski initiates turns more quickly and precisely.

With Low Camber, the ski center is slightly elevated and the contact points are moved toward the ski center. The effective edge is consequentially less, and the ski is more playful and forgiving.

We build our Kästle skis with classic camber and distinguish between Standard Camber and Low Camber.

Benefits of Camber in Kästle Skis:

With Standard Camber, the ski center is clearly elevated and the contact points to the snow are far forward and back. The effective edge is longer and the ski initiates turns more quickly and precisely.

With Low Camber, the ski center is slightly elevated and the contact points are moved toward the ski center. The effective edge is consequentially less, and the ski is more playful and forgiving.

Be the first to hear about new Kästle products, news, sales, demos and events.