Nature is our most important asset. From the beautiful trails on cross-country skis, to the deep snow that give us the best powder days, to the highest peaks that we climb on our touring skis. They are not only a guarantee for the economic success of our industry, they are also our home.

At the same time, they are also a home for our customers. We know that when our customers choose our products, they are placing their trust in us.

Nature is our most important asset. From the beautiful trails on cross-country skis, to the deep snow that give us the best powder days, to the highest peaks that we climb on our touring skis. They are not only a guarantee for the economic success of our industry, they are also our home.

At the same time, they are also a home for our customers. We know that when our customers choose our products, they are placing their trust in us.

Our responsibility, the Kästle "Responsibility", covers a broad spectrum: from the careful selection of our materials to investments in new technologies for resource-saving and recyclable production processes to the end product. This also includes fair and equal working conditions for our employees as well as appreciative cooperation and communication at eye level with our dealers, athletes and brand ambassadors.

Our responsibility, the Kästle "Responsibility", covers a broad spectrum: from the careful selection of our materials to investments in new technologies for resource-saving and recyclable production processes to the end product. This also includes fair and equal working conditions for our employees as well as appreciative cooperation and communication at eye level with our dealers, athletes and brand ambassadors.

The choice of wood is determined by the desired properties of the ski in terms of stiffness, grip, stability, and weight. If the final product is to be stable, we choose a wood with a higher density, such as poplar or beech. A ski that should convince its rider with lightness and float, usually contains a lighter wood, such as paulownia. In many cases, however, we use a combination of different types of wood to meet all requirements. These are glued together and only then pressed with the remaining layers.

But why wood anyway? No other substance can provide the ski with the desired handling characteristics as well as this material - and retain them over a longer period of time. It is quite simply THE quality feature, which is why not only every Kästle has a wood core, but special attention is paid to its origin in the selection as well. Thus, we use up to almost 80% domestic woods, whose main supplier is located in Switzerland.

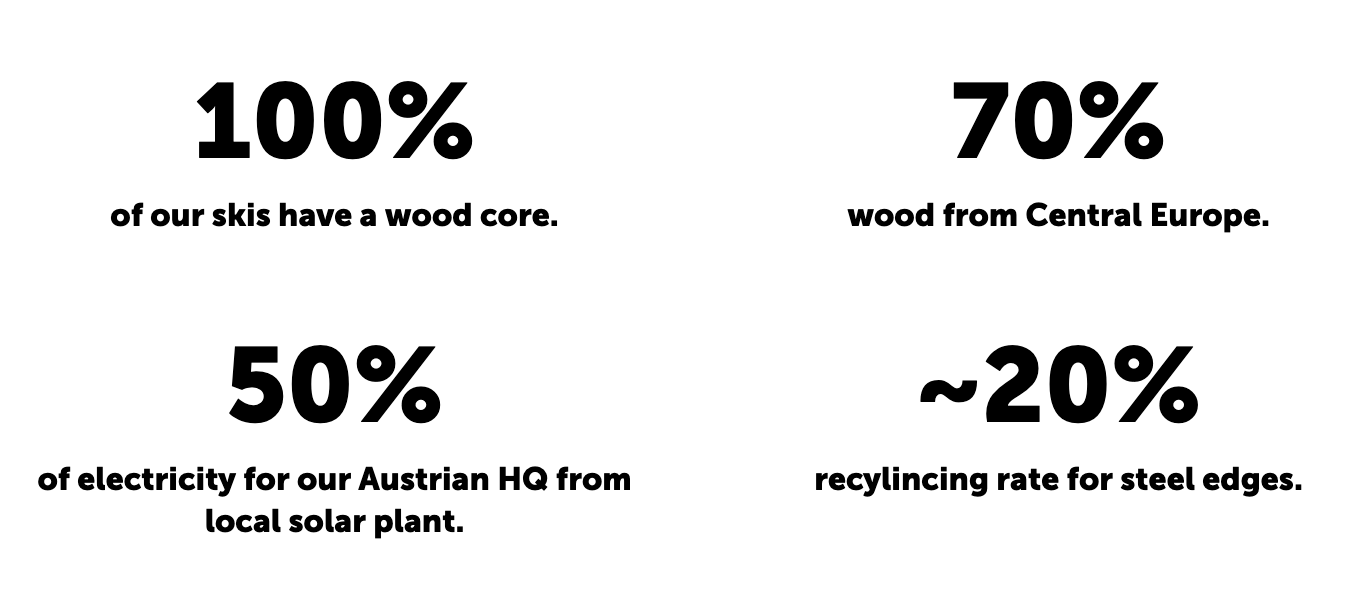

We use wood as a core component of our construction in every single one of our skis: from children's skis to rental skis and World Cup skis. Around 70% of our wood comes from Central Europe. FSC certification is our minimum requirement for our wood stocks.

We obtain up to 20% of our steel edges from recycled materials.

We use wood as a core component of our construction in every single one of our skis: from children's skis to rental skis and World Cup skis. Around 70% of our wood comes from Central Europe. FSC certification is our minimum requirement for our wood stocks.

We obtain up to 20% of our steel edges from recycled materials.

We naturally comply with all legal standards, e.g. the Clean Air Act in our main production facility, which regulates the framework for protecting the ambient air and preventing air pollution.

Pre-pregging is gradually replacing wet lamination in ski production. This optimizes working conditions and the durability of the end products.

50% of the annual energy requirement at the headquarters in Hohenems is covered by renewable energy from solar panels on our building.

We naturally comply with all legal standards, e.g. the Clean Air Act in our main production facility, which regulates the framework for protecting the ambient air and preventing air pollution.

Pre-pregging is gradually replacing wet lamination in ski production. This optimizes working conditions and the durability of the end products.

50% of the annual energy requirement at the headquarters in Hohenems is covered by renewable energy from solar panels on our building.

Our responsibility in the area of logistics:

Our responsibility in the area of logistics:

Be the first to hear about new Kästle products, news, sales, demos and events.